DirectCommand Granular Applicator®

DirectCommand Granular Applicator® will transform the application process, providing maximum control and efficiency.

See DirectCommand Granular Applicator® in Action

See how DirectCommand Granular Applicator®

Right coverage across the entire field

DirectCommand Granular Applicator's® features are built ...

AutoSwath

Variable Rate

Easy Reporting

Solar Modules

Produce electricity even on cloudy days, usually around 10%-20%.

Low Maintenance

This is because there are no moving parts in the solar system.

DirectCommand Granular Applicator® Features

Precise Nozzle Control for Consistent Coverage

A nozzle-by-nozzle advantage

RightSpot uses Blended Pulse® technology to achieve consistent coverage and reduced skips. Pulsing nozzles maintain a precise user-defined boom pressure allowing the operator to achieve a consistent rate and droplet size at a wider variety of speeds and across difficult terrain.

Inconsistent droplet size = converage issues

Without nozzle-by-nozzle technology, achieving consistent coverage across the entire field is difficult. RightSpot monitors and maintains the right droplet size prescribed for the product, ensuring the right amount of product applied to do its job effectively while reducing risk of drift to neighboring crops.

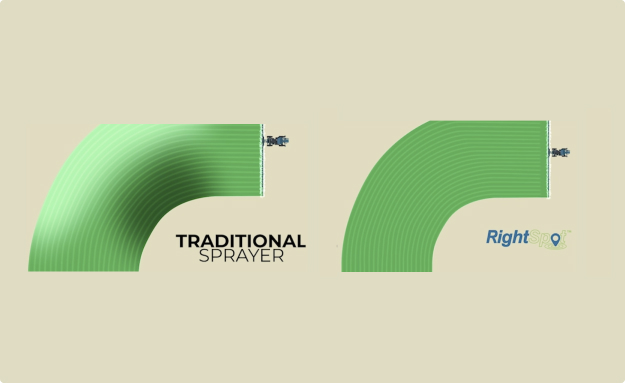

Steady Coverage Around Corners

When spraying along contours, RightSpot adjusts flow rates to match the speed of each nozzle—increasing flow on faster outer nozzles and decreasing it on slower inner ones. This precision prevents both over- and under-application, ensuring accurate coverage throughout the field, reducing crop damage, pest resistance, and product waste.

When It Comes to Granular Application,

Be InCommand

1. AutoSwath

Reduces overapplication and product waste by automatically turning the applicator on/off based on field boundaries and already-applied areas as it passes over the field.

2. Container Sequencing

An easy way to allow for application of the same product (discrete products or blends) sequentially from multiple containers.

3. Rate Control

Control, adjust and record field application based on target rates or variable rate prescription.

4. Smart Report

Automatically generate SmartReport PDFs that provide location, product information, applied totals, as-applied maps and more right from the display.

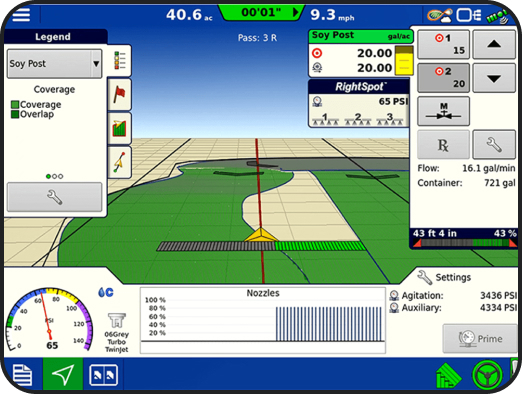

Integrate with InCommand displays for industry-leading visibility and control

“RightSpot's precision control is exactly what our farm needed.”

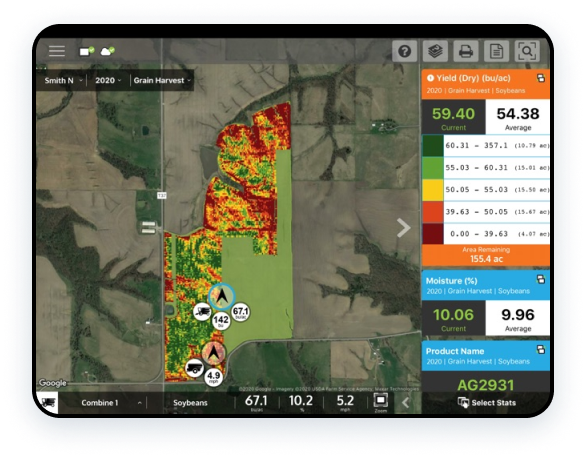

Know Exactly What's Happening in the Field

Share variable rate prescriptions from the office to the machine, maps and guidance lines, rate applied and container level to get field progress and know exactly when you need a refill.

Spinner Spreader Control

Apply up to five products with control based on spinner speed and bin-level monitoring. Container sequencing allows for sequential application of multiple products.

Strip-Till Fertilizer Control

Control up to three granular products while simultaneously controlling the anhydrous and nitrogen stabilizer.

RightSpot Tech Specs

RightSpot FAQs

How does RightSpot handle varying field conditions?

RightSpot independently controls flow rate and pressure, allowing for consistent droplet size and application rate, even over challenging terrains and at different speeds.

What is Blended Pulse® technology and how does it benefit my spraying process?

Tincidunt elit magnis nulla facilisis. Dolor sagittis maecenas. Sapien nunc amet ultrices, dolores sit ipsum velit purus aliquet, massa fringilla leo orci.

Can RightSpot reduce the risk of drift to neighboring crops?

Tincidunt elit magnis nulla facilisis. Dolor sagittis maecenas. Sapien nunc amet ultrices, dolores sit ipsum velit purus aliquet, massa fringilla leo orci.

What advantages does turn compensation offer with RightSpot?

Tincidunt elit magnis nulla facilisis. Dolor sagittis maecenas. Sapien nunc amet ultrices, dolores sit ipsum velit purus aliquet, massa fringilla leo orci.

How does RightSpot adapt to changes in spraying speed?

Tincidunt elit magnis nulla facilisis. Dolor sagittis maecenas. Sapien nunc amet ultrices, dolores sit ipsum velit purus aliquet, massa fringilla leo orci.

Can RightSpot integrate with existing spraying systems?

Tincidunt elit magnis nulla facilisis. Dolor sagittis maecenas. Sapien nunc amet ultrices, dolores sit ipsum velit purus aliquet, massa fringilla leo orci.

DirectCommand Granular Applicator® Resources

DirectCommand Granular Feature User Guide

Already have Ag Leader products? See our full library of manuals.

View Manual

Strip Till Feature User Guide

Already have Ag Leader products? See our full library of manuals.

View Guide

DirectCommand Granular Installation Instructions

Already have Ag Leader products? See our full library of manuals.

View Guide